Frame welding workshop site

* More than 20 new fully automatic welding robots

* Fully automatic product welding process, with a production capacity of 100000 sets/year

* Ensure batch stability and accuracy of product welding processes

车架焊接车间现场

* 拥有20多台新型的全自动焊接机器设备

* 全自动的产品焊接,车架生产能力可达10万套/年

* 充分确保产品在焊接过程的批次稳定性和精确性

Manual fine grinding

* 100% manual re inspection and polishing after the completion of the product welding process

* Fine surface treatment enables products to achieve better electrophoretic/powder spraying effects

手工精细打磨

* 产品焊接工序完成后100%人工复检和打磨

* 精细的表面处理,使产品获得更好的电泳/喷粉效果

Different types of pipe bending equipment

*We have several different types of pipe bending equipment to fully meet the production needs of various types of products

*Control the process accuracy of components, fully reduce production costs, and improve customer market competitiveness

不同类型的大型弯管设备

* 拥有数台不同类型的弯管大型设备,可以完全满足各类型产品的生产需求

* 保证零部件的工艺精度,充分降低生产成本,提高客户市场竞争力

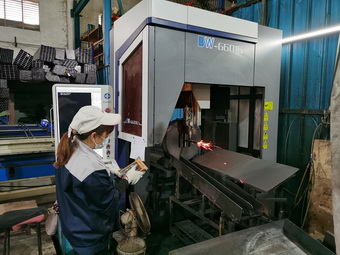

Fully automatic CNC pipe cutting/drilling equipment

*Accurate pipe cutting and drilling to ensure the accuracy of parts produced by the product

*Reduce the consumption of raw materials and reduce the production cost of products

*Safe production and improve production efficiency

全自动管材数控切割/开孔设备

*精准的管材切割与开孔,保证产品生产的零件准确性

*降低原材料的损耗,缩减产品的生产成本

*安全生产,提高生产效率

车架产品包装发货照片

Photo of frame product packaging and delivery

.